Aluminum

We help optimize efficiency in the aluminum industry through the strategic application of carbon or graphite in essential processes such as degassing, floating, casting and extrusion. Our offering includes synthetic graphite in various forms, such as powder, lances, fluxing tubes, plates and rods, designed to meet the exacting demands of each specific application.

Applications

Discover the wide range of applications of graphite in the industry.

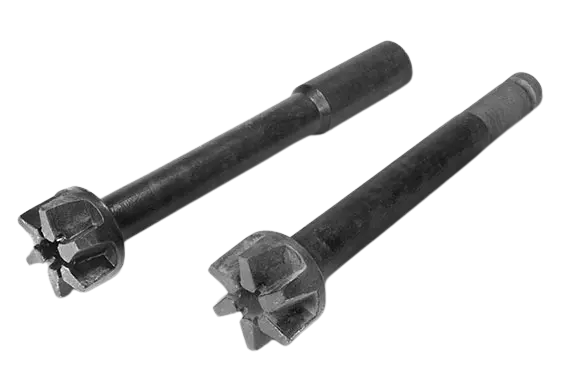

Fluxing Tubes

Flow tubes or graphite lances are used in the injection of gases during the smelting process, eliminating slag and purifying metals through the flotation of impurities.

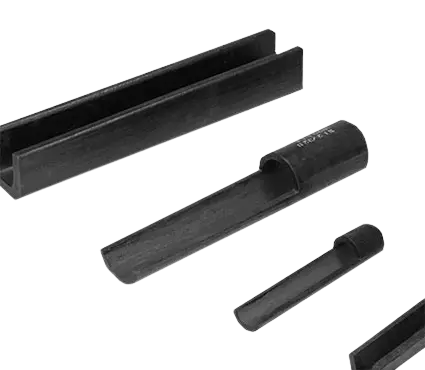

Casting Chutes

These chutes, made of graphite plates or machined pieces, facilitate the handling of molten metals. The properties of graphite prevent the adhesion of metal to the surface and avoid the formation of crust on the walls, especially in areas where the flow velocity decreases.

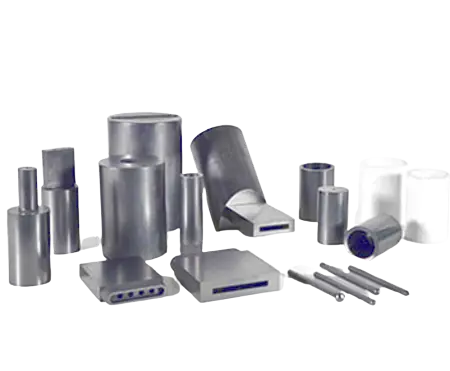

Extrusion Dies

These are machined graphite components used in the production of smooth pipes, wires, profiles and other extruded products.

Crucibles and Ingot Molds

Crucibles are containers used for melting, transporting and casting ferrous and non-ferrous metals. On the other hand, ingot molds are graphite molds used for the production of ingots, mainly in the production of precious metals, although they also find applications in the iron and steel industry.

Lubricants and Suspensions

Lubricants and suspensions of graphite applied by painting or dripping are used as release agents or anti-adhesives. Their application is specifically adapted to each case, with advantages over oil-based lubricants, since they do not burn, maintaining a thin release layer between the mold and the cast part.