Electrical

The requirements of the electrical industry for graphite are diverse. Notable products include: electrical contacts for trams and overhead cranes, brushes for electric motors, and molds for cable melting, among others.

Applications

Discover the wide range of applications of graphite in the industry.

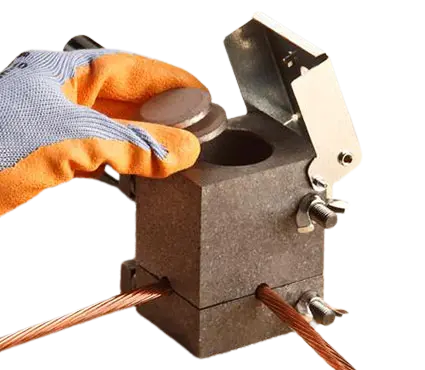

Graphite Molds for Exothermic Soldering

In the context of diversified electrical applications, wire fusing is carried out by an exothermic welding process, where a graphite mold is used. This mold not only serves as a container, but also plays a crucial role in the efficiency of the process by housing an internal flux. Exothermic welding, by utilizing the graphite mold precisely, ensures a durable and reliable electrical connection, which is especially crucial in critical applications such as electrical contacts for trams, overhead cranes, and other critical electrical infrastructure. This approach, backed by the quality and precision of our graphite molds, contributes to excellence in the execution of high-demand electrical projects.

Graphite Grains and Graphite Fragments

In the grounding of electrical circuits, graphite grains of various grain sizes are used to improve the electrical flow to the ground in discharge situations. These are essential elements to safeguard both equipment and personnel against static discharges or short circuits.

Chemical

In the chemical industry, graphite excels as a release agent, powders, stirring bars and specialized lubricants.

Electroerosion

In the EDM industry, the essential machinery includes electrodes previously machined with traditional methods, where the quality of the graphite directly determines the finish and definition of the resulting parts.