Metal Mechanics

The versatility of graphite, in its various presentations and grades, positions it as an indispensable ally in the metalworking industry. Its characteristics, such as self-lubrication, resistance to thermal and chemical shock, as well as its variability in softness or hardness (depending on the grade and subsequent treatment), allow the manufacture of mechanical components for various applications. From solid graphite bars, blocks and plates for machining mechanical seals, bushings, inserts, to centrifugal and vacuum pump blades, among other uses, the different grades and presentations of graphite are found in countless mechanical applications and in the metal-mechanical industry in general. In addition, graphite lubricants and powders find application in processes or situations that require dry self-lubrication, as well as resistance to high temperatures.

Applications

Discover the wide range of applications of graphite in the industry.

Centrifugal Pump Blades (Vanes)

Also known as vanes, they are used in centrifugal pumps to create a sweep inside the vacuum chamber (in the case of vacuum pumps) or in the pumping chamber (in the case of regular pumps).

Metal Bushing Inserts

For the free rotation of shafts and rods, graphite inserts are added to bronze or copper bronze or copper metal bushings. In this way, friction is reduced and the free rotation of the and ensure the free rotation of the mechanical element.

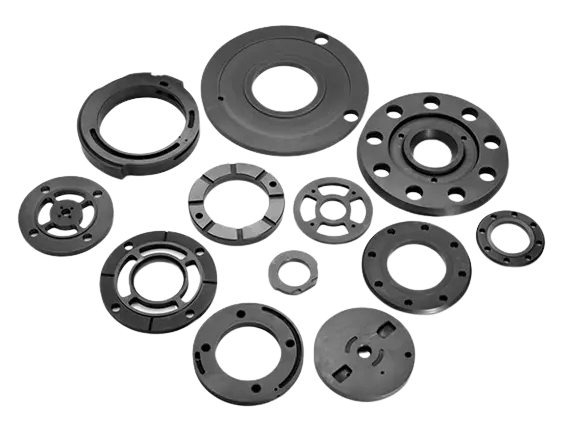

Mechanical Seal Faces

Graphite mechanical seal faces are used for sealing transmissions and compartments with rotating mechanical compartments with rotating mechanical components such as shafts and lances. They exert pressure against the wall of the compartment to be sealed. Because of their components can rotate freely without loss of lubricating fluids.

Lubricants and suspensions

Lubricants and suspensions of graphite are used with paint-type or drip application as release agents or anti-adherents. Their use is specific to each application. There are different grades and different vehicles to produce suspensions suitable for the processes. The engineering of the formulas behind them allows a thin release or lubricating layer to be maintained between the metal elements at all times.

Graphite Greases

They are used to lubricate machinery, shafts, gears, and other transmissions at low speeds, as they possess additional qualities compared to regular lithium greases. The pasty consistency is more resistant to high operating temperatures, allowing for longer-lasting lubrication.