Metallurgy

Some of the most requested presentations of carbon or graphite products in the metallurgical industry include crucibles, furnace components, thermal insulation, sintering molds, molds for drilling tubes, plates, and molds for inert gas welding. In addition, other machined products such as spillways, channels, trays, and plates for handling different metals in liquid state stand out. The resistance of graphite to thermal and chemical shock facilitates the handling of metals, and its self-lubricating properties reduce slag accumulation on walls, offering a self-releasing effect.

Applications

Discover the wide range of applications of graphite in the industry.

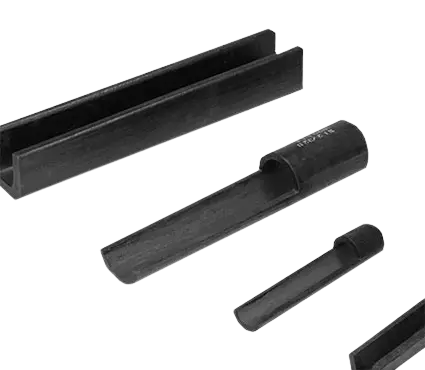

Pouring Channels

Pouring channels are channels made with plates or machined graphite pieces to manage the flow of molten metals. Graphite properties prevent metal adhesion, avoiding crust formation on walls where flow velocity decreases.

Graphite Mortar

Graphite mortar is a mixture of graphite with a pasty and malleable appearance that solidifies when dried. This type of mortar is used in various casting processes together with refractory material.

Crucibles and Molds

Crucibles are containers used in the smelting, transportation, and casting of ferrous and non-ferrous metals. On the other hand, molds are graphite molds designed for the production of ingots, especially of precious metals, although they also find application in metallurgy.

Lubricants and Suspensions

Graphite lubricants and suspensions, applied by paint or dripping, serve as release agents or anti-adhesives. Although their application varies depending on the context, they present advantages over oil-based lubricants by not burning, ensuring a precise release layer between the mold and the cast piece.

Metal Mechanics

In the metalworking industry, graphite offers versatility for mechanical components, lubrication, and specialized applications.

Siderurgy

Various grades of graphite and carbon are used in the iron and steel industry for the production of crucibles, ingot moulds, electrodes, mortars and lubricants.