Siderurgy

Iron, steel, and alloy production is one of the most important economic drivers worldwide. The demand for steel is influenced by other industries such as construction and transportation, as they require large quantities of products like rods, plates, and tubes for building construction and infrastructure, railways, ships, and pipelines. Different presentations of graphite and carbon are used according to the smelting, casting, extrusion, and handling of metals at high temperatures.

Applications

Discover the wide range of applications of graphite in the industry.

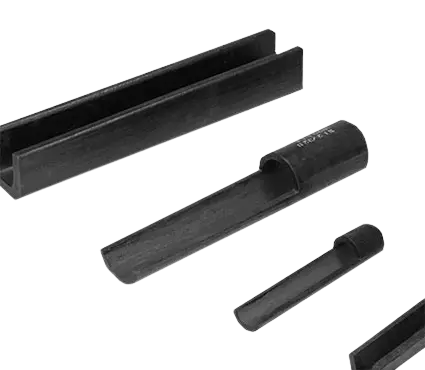

Pouring Channels

Channels for handling molten metals, made with plates or machined graphite pieces. Graphite properties prevent metal adhesion and crust formation on walls where flow velocity decreases.

Smelt Additives

Graphite or high-carbon content material is used as an additive in smelting and steelmaking processes to modify the carbon content in iron or steel.

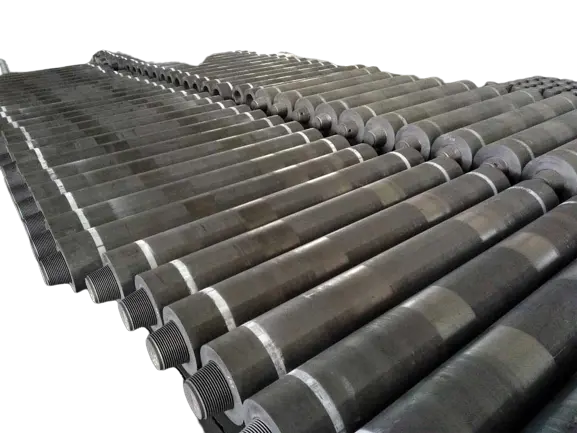

Electric Arc Furnace Electrodes

Essential components in electric arc furnaces for melting scrap, iron, and steel. Graphite electrode production aims to optimize electrical resistivity, sacrificing other properties. In smaller scale processes, other grades of graphite can be used for electrode production.

Graphite Mortar

Mixture of graphite with a pasty and malleable appearance until dry, used in casting processes with refractory material.

Crucibles and Molds

Containers for smelting, transportation, and casting of ferrous and non-ferrous metals. Molds are graphite molds for ingot production (precious metals), also used in steelmaking.

Lubricants and Suspensions

Graphite lubricants and suspensions applied as paint or dripping, act as release agents or anti-adhesives. Designed for specific applications, they offer advantages over oil-based lubricants by not burning, maintaining a thin release layer between mold and cast piece.

Metallurgy

Metallurgy utilizes carbon or graphite products, such as crucibles, molds, and lubricants, known for their versatility and durability.

Transportation

In the transportation industry, graphite plays a crucial role, especially in the railway sector. Leveraging the self-lubricating properties of graphite, we provide grease-free lubrication in iron-to-iron contact, allowing us to project our products towards various applications in the transportation sector.