Chemical

At ESGRAF, we offer special grades of graphite to face corrosive agents and acids in the chemical industry.

We use a wide range of raw materials to manufacture parts such as tubes, nozzles, electrodes for electrochemical dissociation processes, anodes for electroplating, rings, gaskets, seals and bearings. In physical vapor deposition (PVD) processes, such as the production of aluminum-coated polypropylene films, we develop release agents that facilitate the cleaning of the deposition chambers. Our self-lubricating paints help in the removal of slag and prevent the accumulation of vaporized metal on the deposition chamber walls.

Applications

Discover the wide range of applications of graphite in the industry.

Mold Release Agents for PVD

Graphite lubricants applied as paint are used in physical vapor deposition (PVD) processes, where a metal is gasified to deposit it on another object, such as a plastic component. Graphite release agents act as anti-adhesives on the walls of vacuum chambers during this process.

Graphite Powder

Graphite powders play a key role as additives in a wide range of chemical processes and in the production of various materials. They also have the ability to function as pigments.

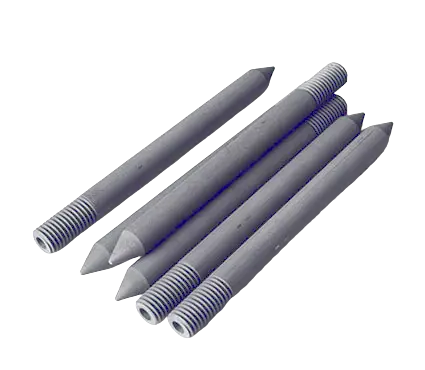

Stirring bars

Graphite stirring rods, thanks to their resistance to chemical attack and impact, are used in the handling and processing of chemical materials.

Lubricants and Suspensions

Graphite lubricants and suspensions are applied as paints or drip applied, acting as release agents or anti-seize agents. Designed for specific applications, they offer various grades and vehicles adapted to each process. The engineering of the formulas ensures a thin and constant layer between the metallic elements.

Aluminum

In the aluminum industry, synthetic graphite is used for casting, extrusion and other applications such as gas injection, weirs, extrusion dies, crucibles and lubricants.

Electrical

In the electrical industry, graphite grains are used to improve the electrical flow in circuit grounding, essential for protection against static discharges and short circuits.