Electroerosion

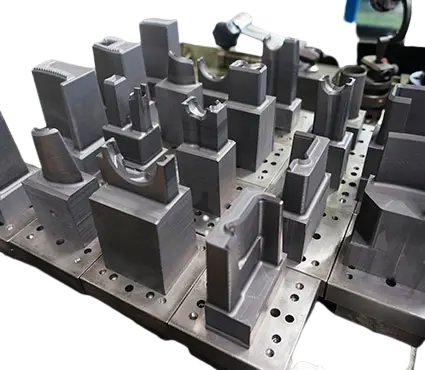

The die sinking EDM process, also known as Electron Discharge Machining (EDM), is a machining method in which the temperature of the graphite electrode is raised by electric current while it is immersed in some metal. ESGRAF participates in this process for the production of high density molds used in packaging and industrial applications. This method is used for the manufacture of plastic injection molds, among others.

Applications

Discover the wide range of applications of graphite in the industry.

Electrodes for EDM

These are essential components in the EDM process. Prior to manufacturing parts by EDM, the graphite electrodes need to be machined by traditional methods such as lathes or milling machines. The grades of graphite required for EDM vary according to the desired quality, which directly influences the surface finish of the part. High purity, high density graphite provides a superior finish and greater definition.